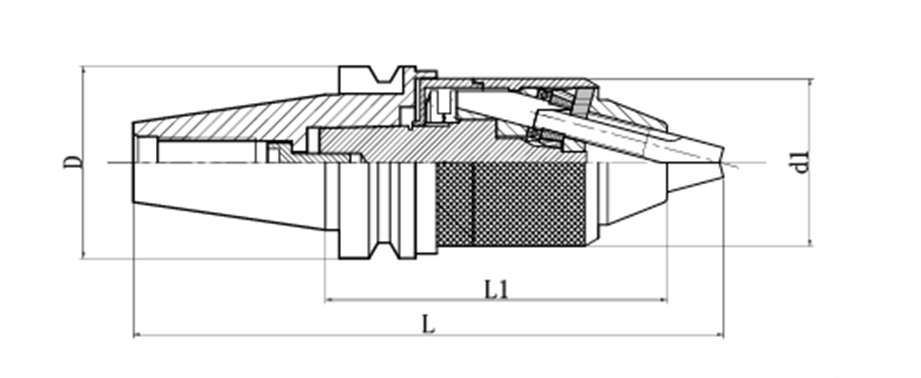

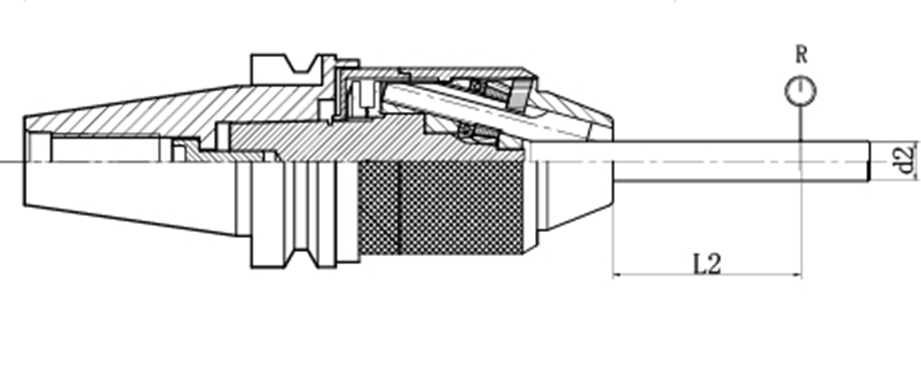

MAS403-BT(JIS B 6339)

|

Model |

L1 |

L |

L2 |

D |

d1 |

d2 |

R |

|||||||

|

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

|

|

BT40-APU13-110 |

110 |

4.331 |

190.4 |

7.496 |

75 |

2.953 |

63 |

2.48 |

55 |

2.165 |

13 |

0.512 |

0.05 |

0.002 |

|

BT50-APU13-120 |

120 |

4.724 |

237 |

9.331 |

75 |

2.953 |

100 |

3.937 |

55 |

2.165 |

13 |

0.512 |

0.05 |

0.002 |

|

BT50-APU16-125 |

125 |

4.921 |

242 |

9.528 |

80 |

3.15 |

100 |

3.937 |

63 |

2.48 |

16 |

0.63 |

0.05 |

0.002 |

DIN-69871-A

|

Model |

L1 |

L |

L2 |

D |

d1 |

d2 |

R |

|||||||

|

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

|

|

DAT40-APU13-110 |

110 |

4.331 |

193.4 |

7.614 |

75 |

2.953 |

63.5 |

2.5 |

55 |

2.165 |

13 |

0.512 |

0.05 |

0.002 |

|

DAT50-APU13-110 |

110 |

4.331 |

226.75 |

8.927 |

75 |

2.953 |

97.5 |

3.839 |

55 |

2.165 |

13 |

0.512 |

0.05 |

0.002 |

|

DAT50-APU16-120 |

120 |

4.724 |

236.75 |

9.321 |

80 |

3.15 |

97.5 |

3.839 |

63 |

2.48 |

16 |

0.63 |

0.05 |

0.002 |

CAT-ANSI B5.50

|

Model |

L1 |

L |

L2 |

D |

d1 |

d2 |

R |

|||||||

|

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

|

|

CAT40-APU13-110 |

110 |

4.331 |

193.3 |

7.608 |

75 |

2.953 |

63.5 |

2.5 |

55 |

2.165 |

13 |

0.512 |

0.05 |

0.002 |

|

CAT50-APU13-110 |

110 |

4.331 |

226.75 |

8.297 |

75 |

2.953 |

98.45 |

3.876 |

55 |

2.165 |

13 |

0.512 |

0.05 |

0.002 |

|

CAT50-APU16-120 |

120 |

4.724 |

236.75 |

9.321 |

80 |

3.15 |

98.45 |

3.876 |

63 |

2.48 |

16 |

0.63 |

0.05 |

0.002 |

The Saper precision short tapping and drilling self-tightening chuck with integrated shank is a high-quality tool used in precision machining operations. This chuck features a short taper design that provides accurate tool alignment and consistent performance, making it an ideal choice for a wide range of applications.

One of the key features of the Saper precision short tapping and drilling self-tightening chuck is its integrated shank. This design eliminates the need for separate components, making it easy to install and use. Additionally, the compact design of the chuck allows it to be used in confined spaces, making it ideal for use in a variety of machining applications.

Another significant advantage of the Saper precision short tapping and drilling self-tightening chuck is its high level of precision. This chuck is designed to provide accurate tool alignment, ensuring that the tool remains stable and in place during use. This level of precision is essential for ensuring consistent and high-quality results in precision machining operations.

The Saper precision short tapping and drilling self-tightening chuck with integrated shank is typically made from high-quality materials such as hardened steel or carbide. These materials ensure that the chuck is durable and able to withstand the rigors of heavy-duty machining operations. Additionally, the chuck requires minimal maintenance, making it a cost-effective solution for machinists.

To ensure reliable and consistent performance, it is essential to follow proper installation and maintenance procedures when using the Saper precision short tapping and drilling self-tightening chuck with integrated shank. This typically involves carefully inserting the tool into the chuck and tightening the chuck jaws to secure the tool in place. It is also important to inspect the chuck regularly for wear and damage and replace any worn or damaged components as needed.

In summary, the Saper precision short tapping and drilling self-tightening chuck with integrated shank is a high-quality tool that provides accurate tool alignment, consistent performance, and ease of use. By selecting the right integrated shank chuck for your specific machining needs and following proper installation and maintenance procedures, you can ensure reliable and consistent performance for years to come.

Features:

● Drill chuck and tool handle are integrated, drill chuck not fall off under heavy cutting

● Loosen and clamping by manual, easy operating, saving clamping time

● Strong clamping torque, self-locking device, drilling and tapping