|

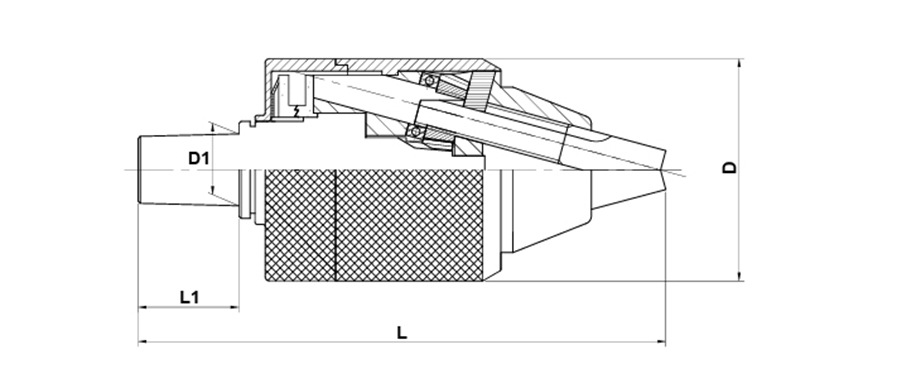

Model |

Clamping range |

D |

D1 |

L1 |

L |

|||||

|

mm |

in |

mm |

in |

mm |

in |

mm |

in |

mm |

in |

|

|

J0113M-MT2D |

1-13 |

0.039-0.512 |

50 |

1.968 |

17.78 |

0.7 |

25 |

0.984 |

124 |

4.882 |

|

J0113-MT2D |

1-13 |

0.039-0.512 |

55 |

2.165 |

17.78 |

0.7 |

25 |

0.984 |

131 |

5.157 |

|

J0113-MT3D |

1-13 |

0.039-0.512 |

55 |

2.165 |

23.825 |

0.938 |

26.5 |

1.043 |

132.5 |

5.217 |

|

J0116-MT2D |

1-16 |

0.039-0.63 |

63 |

2.48 |

17.78 |

0.7 |

25 |

0.984 |

145 |

5.709 |

|

J0116-MT3D |

1-16 |

0.039-0.63 |

63 |

2.48 |

23.825 |

0.938 |

26.5 |

1.043 |

146.5 |

5.768 |

Tapping and drilling self-tightening chucks with integrated shanks are critical tools in a machine shop, providing a secure and stable connection between the tool and the machine spindle. One of the most popular designs of integrated shanks is the Morse short taper, which is widely used in various machining operations.

The Morse short taper is a standardized method for securing tools in a machine spindle, which is commonly used in drilling and tapping operations. The taper is designed to provide accurate tool alignment and consistent performance, while the short length allows for a compact design that is ideal for use in confined spaces.

One of the primary benefits of using tapping and drilling self-tightening chucks with integrated shanks using the Morse short taper design is their versatility. These chucks are available in various sizes and styles to suit different machining requirements, and they can be used with different types of tools, including drilling bits and taps.

Another significant advantage of the Morse short taper design is its ease of use. The integrated shank and chuck eliminate the need for separate components, saving time and effort during tool changes. Additionally, the compact design of these chucks makes them easy to store and transport.

tapping and drilling self-tightening chucks with integrated shanks using the Morse short taper design are typically made from high-quality materials such as hardened steel or carbide. This ensures that they are durable and able to withstand the rigors of heavy-duty machining operations. They also require minimal maintenance, making them a cost-effective solution for machinists.

To ensure consistent and reliable performance, it is crucial to follow proper installation and maintenance procedures when using a tapping and drilling self-tightening chuck with an integrated shank using the Morse short taper design. This typically involves carefully inserting the tool into the chuck and tightening the chuck jaws to secure the tool in place. It is also essential to inspect the chuck regularly for wear and damage and replace any worn or damaged components as needed.

In summary, tapping and drilling self-tightening chucks with integrated shanks using the Morse short taper design are versatile, easy to use, and durable tools that are essential for various machining operations. By selecting the right integrated shank chuck for your specific machining needs and following proper installation and maintenance procedures, you can ensure consistent and reliable performance for many years to come.