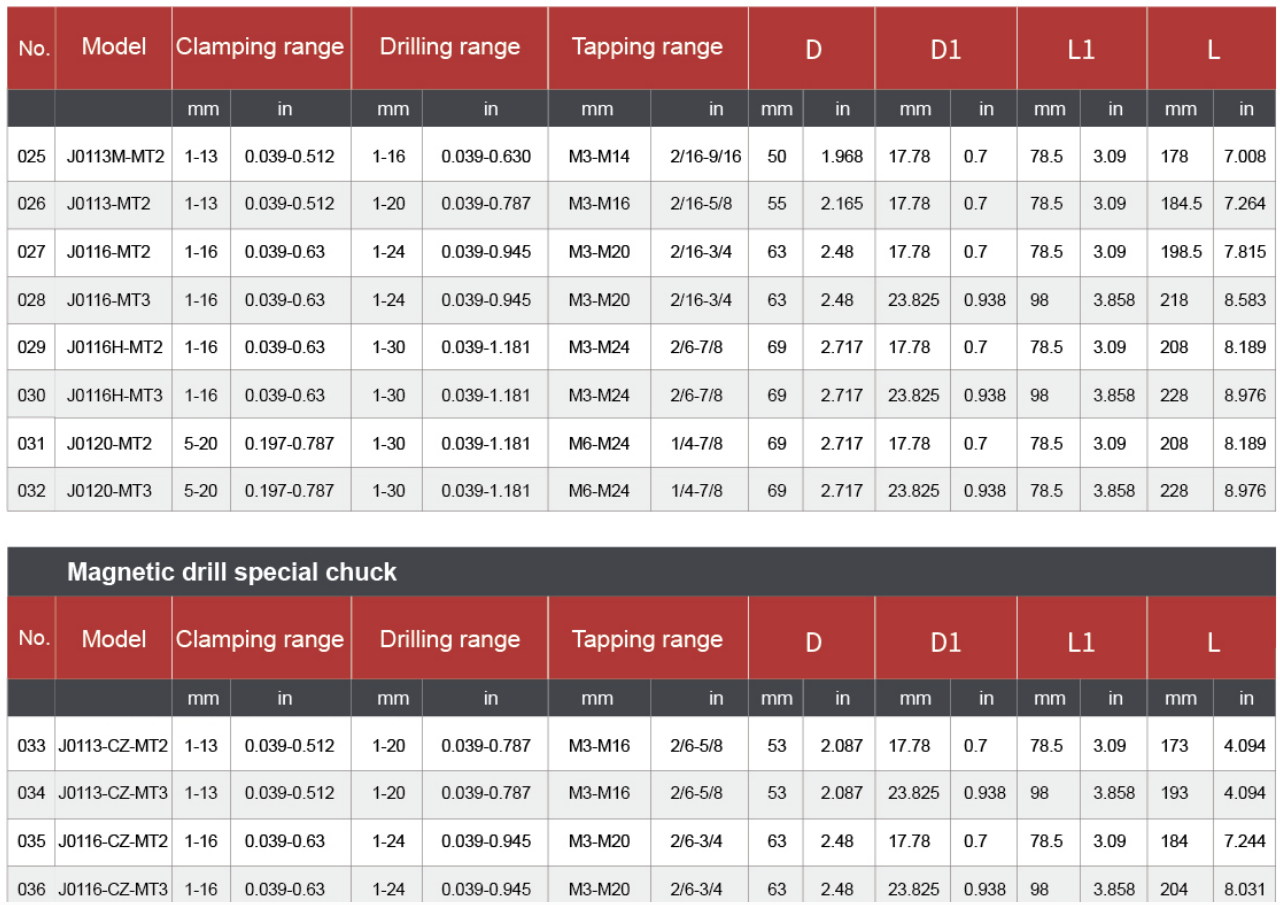

| model | Clamping range | Drilling range | Tapping range | D | D | L1 | L | |||||||

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | |

| J0113M-C20 | 1-13 | 0.039-0.512 | 1-22 | 0.039-0.866 | M3-M16 | 1/16-5/8 | 50 | 1.968 | 20 | 0.787 | 60 | 2.362 | 159 | 6.26 |

| J0113-C20 | 1-13 | 0.039-0.512 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 55 | 2.165 | 20 | 0.787 | 60 | 2.362 | 166 | 6.535 |

| J0116-C20 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 20 | 0.787 | 60 | 2.362 | 180 | 7.887 |

| J0116-C25 | 1-16 | 0.039-0.63 | 1-30 | 0.039-1.181 | M3-M24 | 1/16-7/8 | 63 | 2.48 | 25 | 0.984 | 80 | 3.15 | 200 | 7.874 |

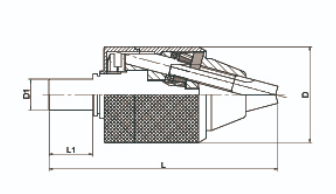

Taper mount tapping and drilling self-tightening chucks are specialized tools that are used to hold and secure drilling bits and taps in place during machining operations. These chucks are essential components of any machining setup and are used extensively in various industries, including aerospace, automotive, and manufacturing.

The taper mount chuck design is based on the Morse taper system, which is a standardized method of securing tools in a machine spindle. Taper mount chucks feature a male taper that is designed to fit snugly into a corresponding female taper on the machine spindle. This provides a secure and stable connection that ensures precise tool alignment and minimizes tool runout.

One of the key advantages of taper mount chucks is their versatility. These chucks can hold a wide range of tool sizes and shapes, including drill bits, taps, reamers, and end mills. This makes them ideal for a variety of machining applications, from drilling and tapping to boring and milling.

Taper mount chucks are renowned for their durability and dependability in addition to their adaptability and simplicity of usage. To endure the demands of heavy-duty machining operations, these chucks are often constructed from high-quality materials such hardened steel or carbide. They also require little maintenance and upkeep to maintain long-lasting functionality.

In order to prevent tool runout and lower the chance of chuck or machine spindle damage while utilizing a taper mount chuck, it is crucial to guarantee appropriate tool installation and alignment. In order to do this, the tool is normally gently inserted into the chuck and the chuck jaws are tightened to hold the tool in place. Additionally, it's critical to routinely check the chuck for wear and damage and to replace any worn or damaged components as needed.

In order to prevent tool runout and lower the chance of chuck or machine spindle damage while utilizing a taper mount chuck, it is crucial to guarantee appropriate tool installation and alignment. In order to do this, the tool is normally gently inserted into the chuck and the chuck jaws are tightened to hold the tool in place. Additionally, it's crucial to routinely check the chuck for wear and damage and replace any worn or damaged parts as necessary.

In general, self-tightening taper mount tapping and drilling chucks are necessary equipment for any machining process. Their adaptability and durability make them perfect for a variety of applications, and they offer a safe and reliable connection for a wide range of tools.By choosing the right taper mount chuck for your specific machining needs and following proper installation and maintenance procedures, you can ensure reliable and consistent performance for years to come.